International Methods for Severe and Total Loss Control

The Foam Wedge Lost Circulation System, capable of sealing fractures up to 40,000 microns, has been successfully implemented by Halliburton in field applications across two Middle Eastern countries (Oman and the UAE).

Challenges in Natural Fracture/Vugular Formations

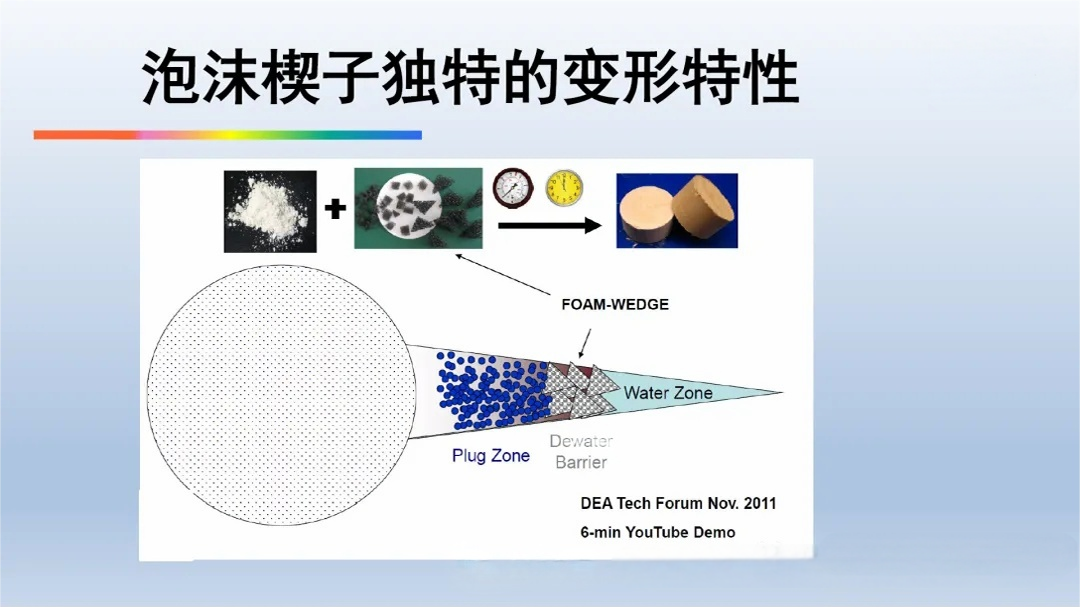

Addressing severe-to-total losses in naturally fractured or vugular formations has long been challenging, particularly in the Middle East. Conventional lost circulation materials (LCMs) often fail due to uncertainty in fracture aperture sizes. However, Halliburton’s Foam Wedge System, combining High Fluid Loss Squeeze (HFLS) and Reticulated Foam LCM (RFLCM), has proven effective, supported by field-tested success.

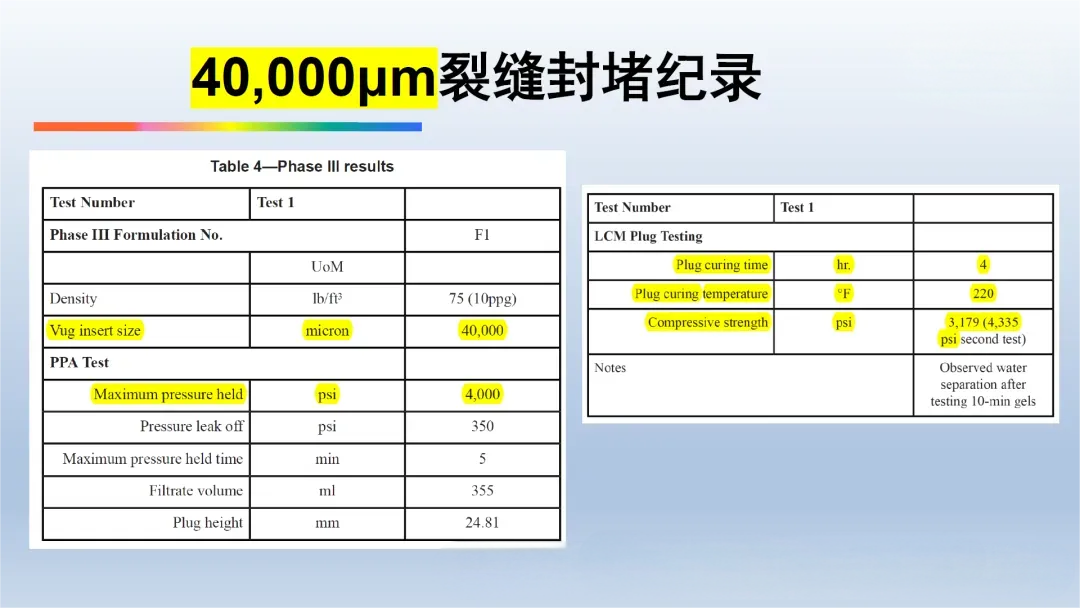

The design and evaluation of LCM treatments were based on successful laboratory tests, demonstrating sealing of fractures up to 40,000 microns.

HFLS and RFLCM Dual Technology: Laboratory and Field Results in Two Middle Eastern Countries (Oman and UAE)

These details include formation characteristics, wellbore size, volume and concentration of LCM mud, as well as the formulation and pumping methods used. The success of the application was demonstrated by the loss rates before and after treatment under both static and dynamic wellbore conditions, highlighting the drilling time saved.

In Oman, the target well experienced static losses of up to 125 barrels per hour (bbl/hr) and dynamic losses of 280 bbl/hr (550 gallons per minute, gpm) to "total losses." The formation was characterized by vugular porosity. The client's goal was to pump an efficient LCM solution to quickly address losses after reaching total depth (TD) and to perform logging operations without the need for cement plugs, thereby saving drilling time. The HFLS and RFLCM treatments were mixed in water, pumped through a circulating sub, and subjected to a circulating squeeze process with gradually increasing pressure. After the squeeze, both static and dynamic loss rates were reduced to zero, allowing operations to safely continue.

In the UAE, the target well used a non-aqueous drilling fluid. Under static conditions, losses ranged from 85 to 200 bbl/hr, while under dynamic conditions (flow rates of 990–1250 gpm), the loss rate was 150 bbl/hr. The formation was characterized by naturally developed fractures. The HFLS and RFLCM components were mixed in base oil, pumped through a circulating sub, and subjected to a circulating squeeze process with gradually increasing pressure. After the squeeze, the static loss rate was reduced to 2–15 bbl/hr, and the dynamic loss rate was reduced to a maximum of 25 bbl/hr (dropping to 5 bbl/hr during drilling), allowing operations to resume.

In technical evaluation tests, the ability to seal laboratory-simulated fractures/vugs with openings of up to 40,000 microns provided confidence that the LCM combination could handle uncertain downhole fracture/vug sizes. Successful field applications resolved severe to total losses, validating the HFLS/RFLCM dual approach. The most significant advantage of the improved LCM technology is the reduction in well construction costs by minimizing drilling time associated with managing severe to total losses.

Benchmarking the above lost circulation system, our company has independently developed two products: the High Fluid Loss Squeeze (HFLS) agent FC-FLS and the Reticulated Foam LCM (RFLCM) agent FC-LCM, both of which achieve performance equivalent to Halliburton's Foam Wedge Lost Circulation System.

Post time: Mar-03-2025